RESEARCH: WORKING PROCESSES

Innovating workplaces beyond the office

At PROTOinc, our expertise in workplace design transcends traditional office spaces. With a rich portfolio spanning non-profit organizations, creative offices, industrial facilities, and agricultural sectors, we’ve honed our skills in diverse work environments. But we’re not just architects interested in spatial outcomes; we’re equally curious about the processes that make our society productive. We delve deep into the intricacies of work processes and protocols, seeking to understand the unique dynamics of each industry — and each client — we serve. In a rapidly evolving world where the definition of work itself is transforming, our research seeks to understand how this is affecting typical, highly specialized forms of the workplace. We explore how different forms of work intersect, overlap, and hybridize, envisioning innovative spaces that adapt to the ever-changing needs of modern society. At PROTOinc, we’re not just building spaces; we’re helping to shape the future of work.

Our past workplace experience has focused on facilities that have very specific and intricate operational demands: automotive, cannabis, multi-mode public, etc. For such projects and clients, circulation, flow, flexibility are of even greater value. These dynamic streams and processes have required us to develop new analytical tools in order to formulate effective architectural responses. There’s an art to this… and informs where we look for inspiration (eg: airports, infrastructure, agriculture, etc.).

Now that the worst of the COVID-19 pandemic is (hopefully!) behind us, our society has been launched into a new era of working with a clear sense that things are very different, but very little clarity on how they are different. This is a challenge that almost all our clients are facing, and has been at the forefront of our conversations recently. Some of the key questions include:

How do the physical attributes of the workplace exacerbate or alleviate issues of productivity and isolation? How can we improve the seamlessness and continuity between working from home versus the office?

How does an organization remain cohesive when staff are rarely in the same place at the same time? How are new hires brought on board, trained, and integrated into the culture/community?

Disparate working environments require radically different space planning and facility strategies. How does one foster a clear and compelling organization culture when the facilities send a message of a scattered and varied identity?

When physical plant budgets contract (why spend so much when people are in only half the time?) how does one balance the “sunk costs” already invested in less-than-ideal facilities versus the capital expenditure involved in creating new, optimized spaces?

Dealing with a very heterogeneous mixture of spaces, in varying states of repair, with radically different working cultures implied in the physical bones of these buildings creates friction. This is not to mention the sheer range of the operational differences between facility programs like office, maintenance, classroom, wildlife care, retail, food service, etc.

RELATED PROJECTS

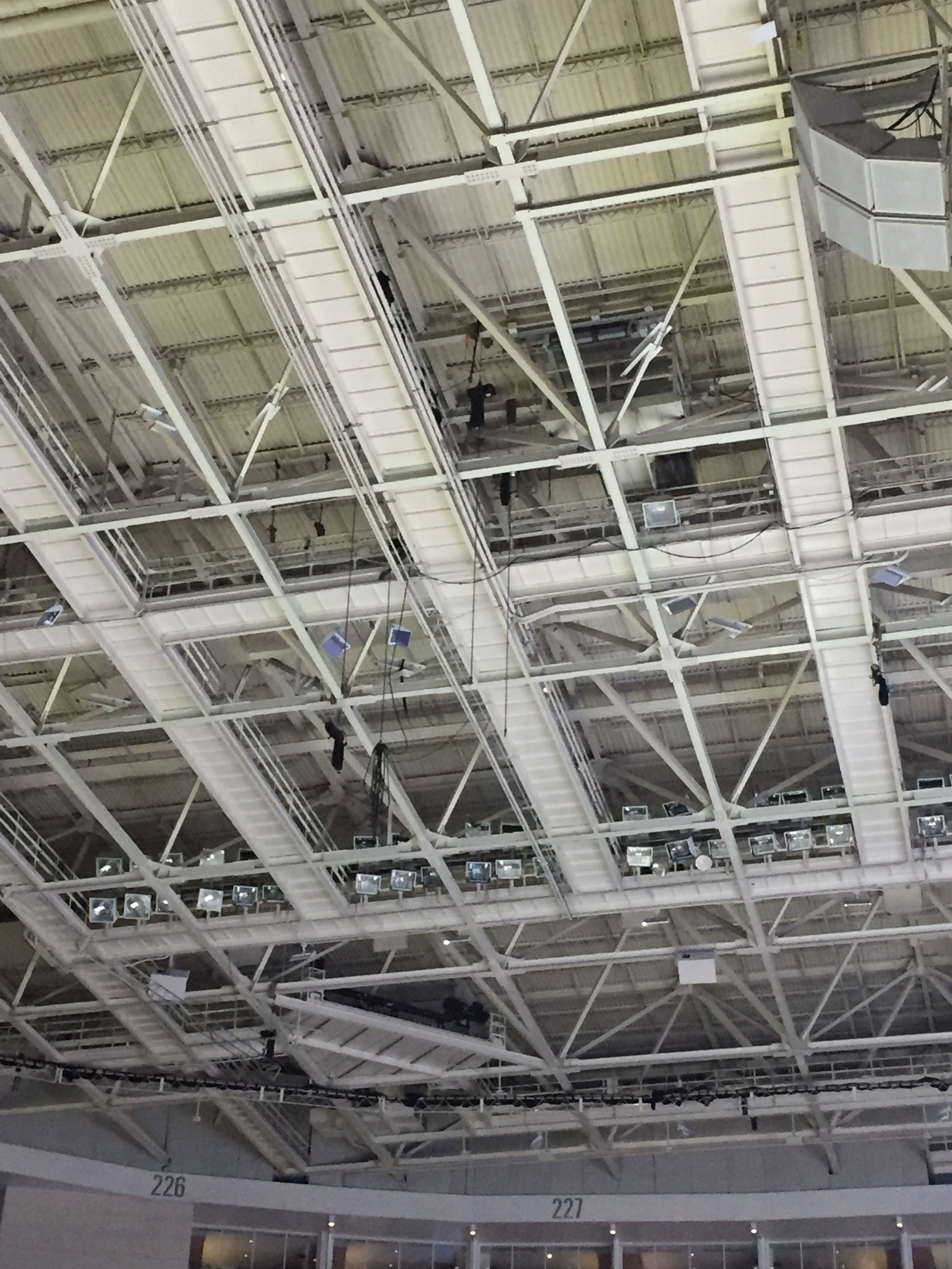

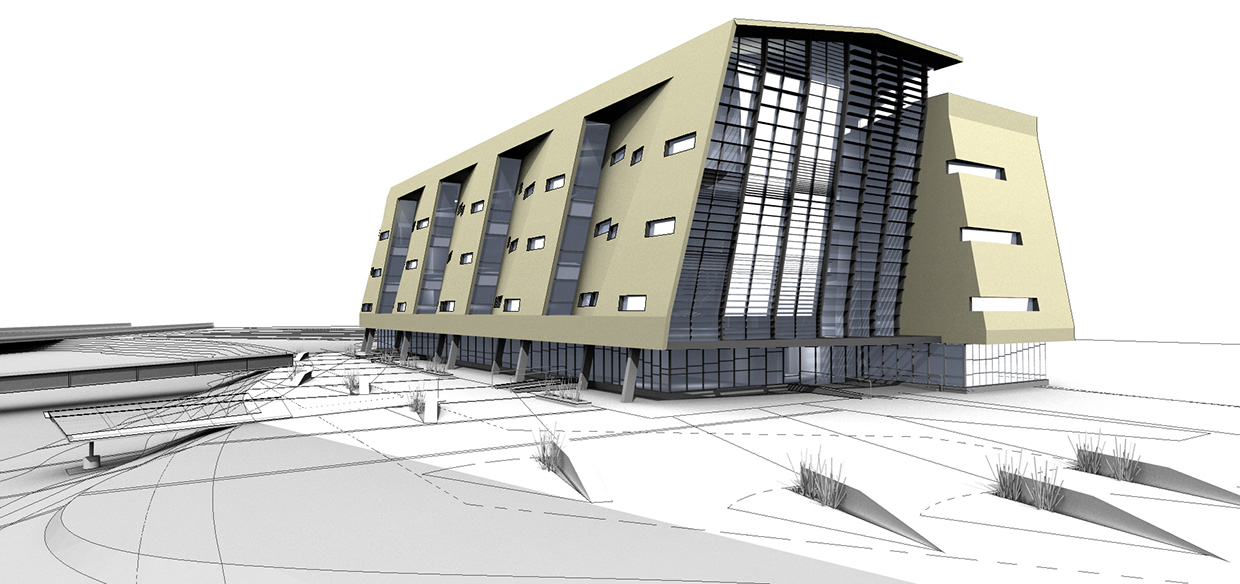

BAIR ISLAND LABS

Multi-tenant research and development space poses a difficult tension between the need for proprietary secrecy and entrepreneurial collaboration. This project for a spec proteomics research center examines the potential of a building to offer both.

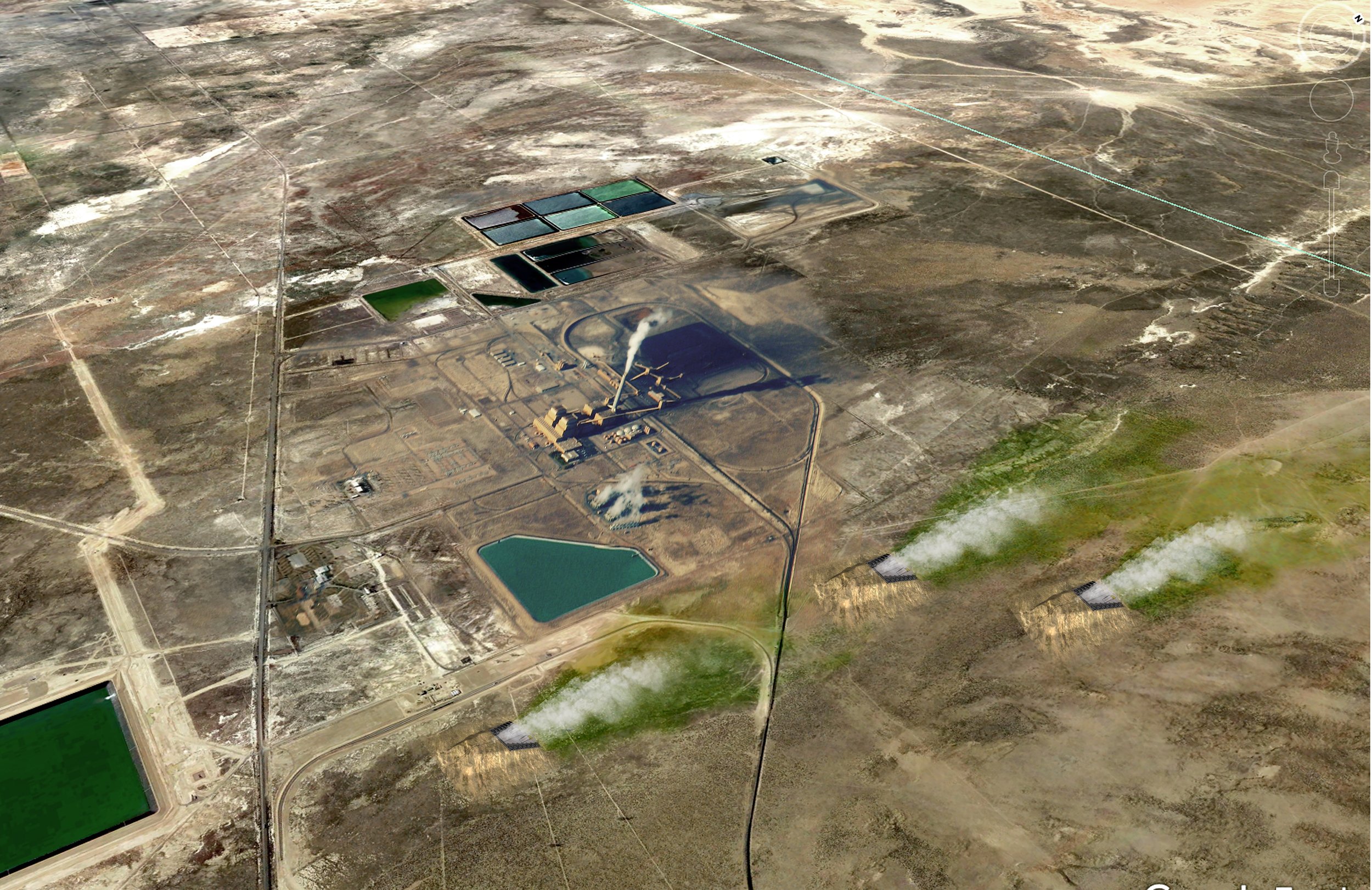

URBAN FARMING

Given the recent collapse of the cannabis cultivation market, how might investments in indoor farming facilities and advances in grow technology be re-tooled for edible crops? And what are the implications for urban agriculture, farm-to-table networks, and food deserts?

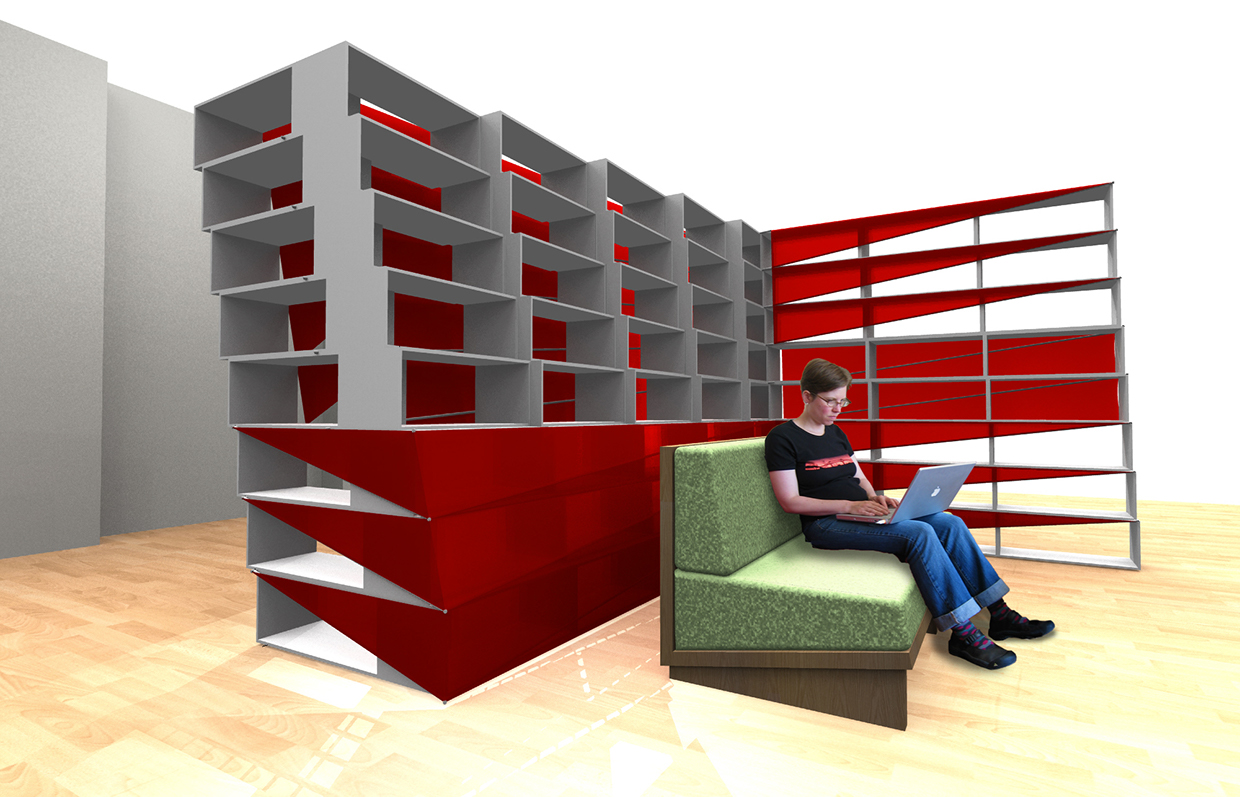

SOLV.TV

Start ups often evolve faster than typical tenant improvement construction techniques can follow. While high-end furniture companies offer an array of sophisticated modular systems to accommodate rapid change, they are often out of reach for many small companies and organizations. How can widely-available off-the-shelf components be retrofitted to serve the same need for quick and easy adaptation?

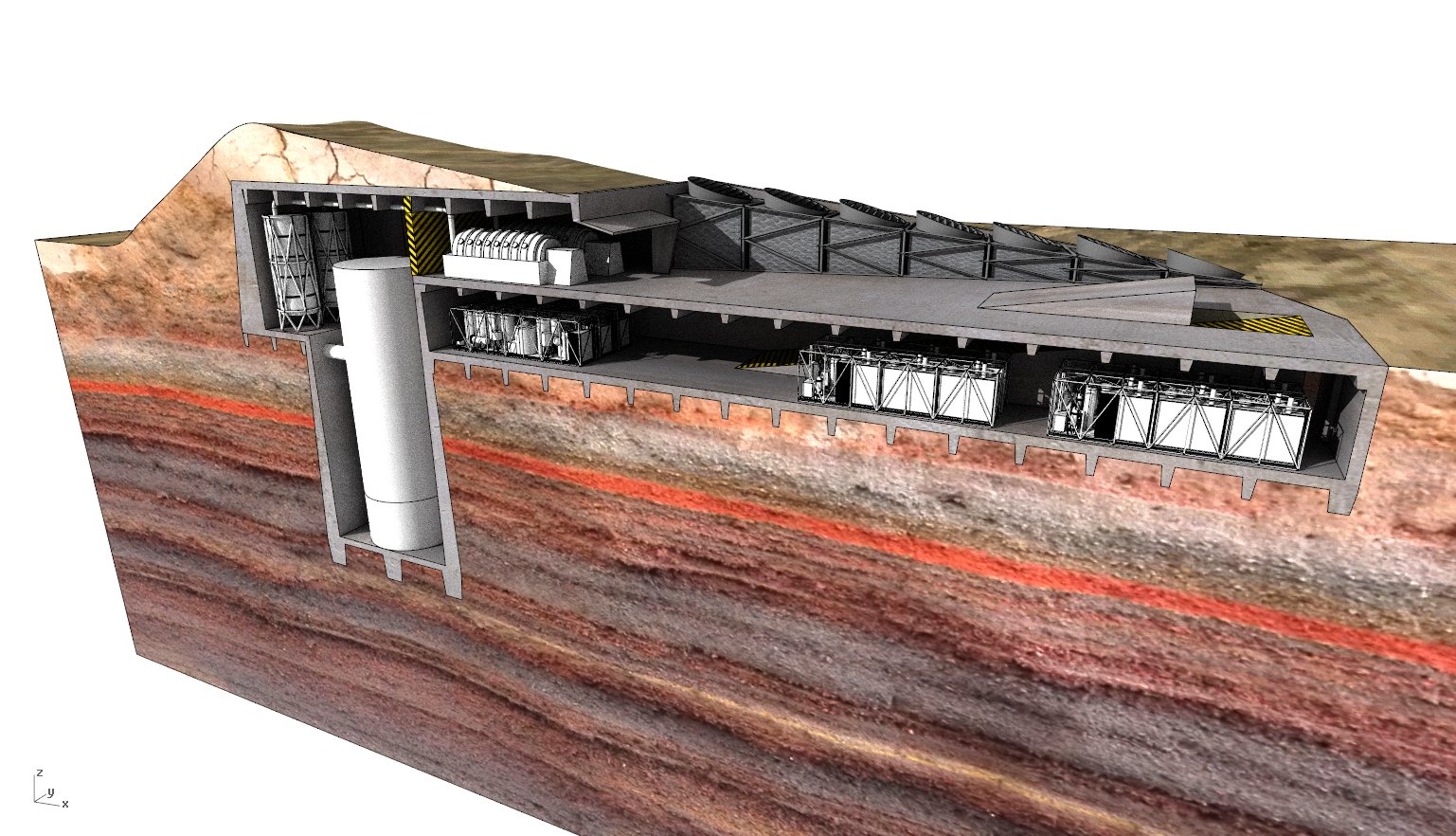

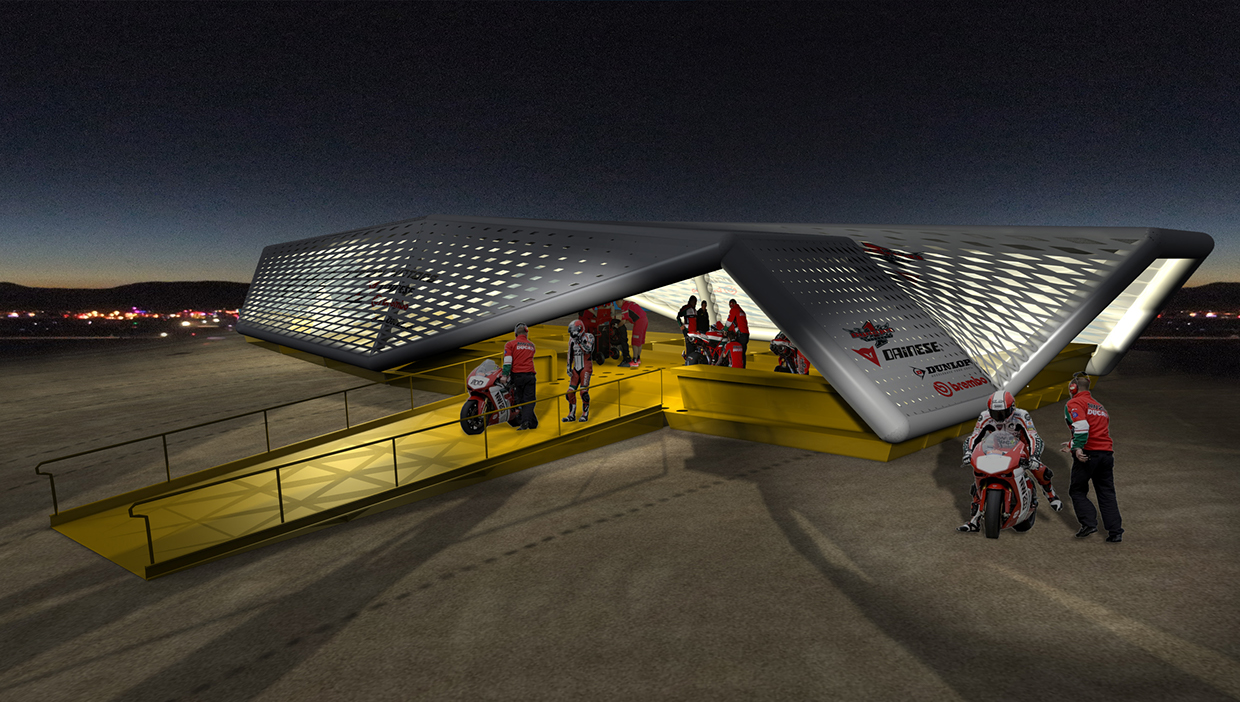

PNEUMAD

Maintenance of even the most sophisticated equipment invariably takes place in a static location, in the most generic of facilities. What if maintenance became mobile — going to where it was needed — and became a front-of-house role instead of back-of-house?